Mexico Industrial Manufacturing

NovaLink has been the premier destination for Mexico industrial manufacturing for 30 years.

With Over 30 Years of Experience in Industrial Manufacturing in Mexico, NovaLink Has a Wealth of Knowledge

NovaLink has been the premier destination for Mexico industrial manufacturing for 30 years. Satisfied clients include Patagonia, Nike, and Franklin Aircraft.

The manufacturing industry in Mexico is vibrant and growing. As an example of nearshore manufacturing services that help businesses produce high-quality complex products for industries like automotive, aerospace, medicine, and apparel at an affordable cost, check out NovaLink.

With the new trade agreements between Mexico, Canada and the United States now in place, full package manufacturing between these nations is now easier and more cost effective than ever:

- There are no tariffs for products made in Mexico and imported into the United States that meet NAFTA rules of origin requirements.

- Lower shipping time for goods to get into the United States

- Lower average cost of shipping

- Lower MOQ

- Lower number of days to start Mexico Industrial Manufacturing operations

- Cost-effective and more productive labor pool

Making the decision to move manufacturing to Mexico doesn’t have to be a complex headache that costs your business money; taking advantage of the Mexico manufacturing advantage with NovaLink, is an easy, seamless process.

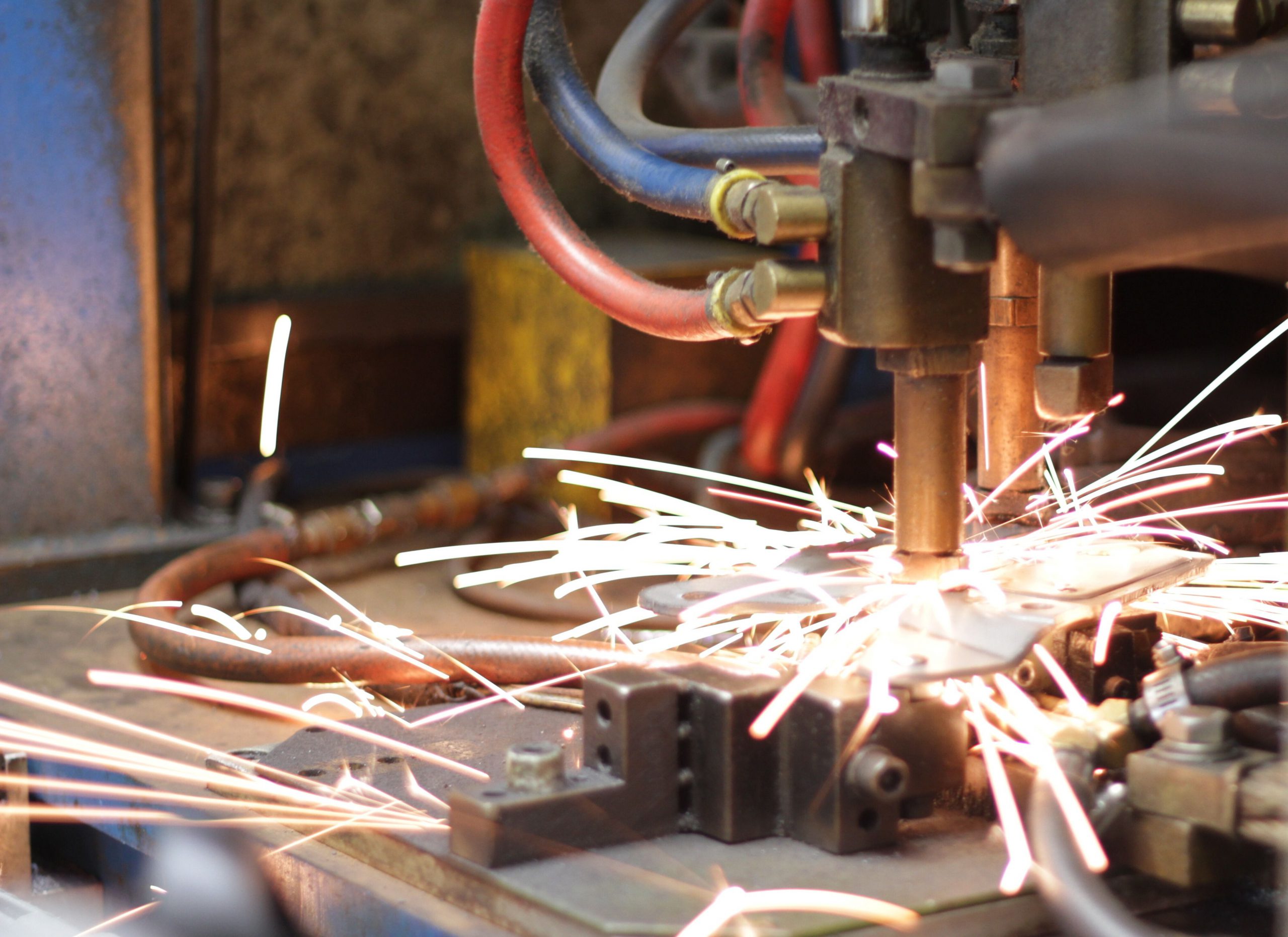

NovaLink Manufacturing Facility Video

NovaLink has released a new video highlighting the versatility of their manufacturing facility in Matamoros, Mexico. In this video, you will be able to see the factory and its associates in action. The video, which was filmed on the floor of the manufacturing facility, illustrates the variety of manufacturing operations and the wide range of skills represented by the workforce. As well as demonstrating NovaLink's commitment to first class manufacturing, the video also emphasizes its commitment to safety protocols for the health of its workers and clients.

Manufactured Products That Can Be Assembled in Mexico

Subassembly is required after the components of your product have been manufactured. A subassembly can be labor-intensive and expensive to manufacture, depending on the complexity of your product. However, as with any complex manufacturing problem, the easiest solution may lie just south of the border: Mexico.

Mexico Industrial Manufacturing Processes Powered by Novalink

Many manufacturing processes can be applied across various industries, and manufacturing companies can use them to tailor production business needs. Here are some examples of manufacturing processes NovaLink uses for its clients in Mexico.

Repetitive Manufacturing

Repeated production processing comprised of dedicated production lines that produce the same or similar items, all year round, usually committed to a known production rate. Minimal setup, little changeover. Operation speed adjustable to customer demand.

Process Manufacturing (Batch)

Allows the use of the “same” production resources for different products. This method of production is capable of creating several items at the same time in a series of production steps. It is important to define minimum order quantity to maintain certain level of efficiency. Once a batch is completed, the equipment, workcell or production line can be entirely switched over to produce the next batch when needed. Batch processing needs to be continued to be efficient.

Discrete Manufacturing

Assembly or production line where the processing steps may be diverse with a large variation of setups and changeover frequencies. Miscellaneous production items or discordant in design. Seasonal production may require altering line setup and usually changeovers require more time. All line layouts adjustments and utilities relocation are made in house, no third party support required.

Job Shop Manufacturing

Defined production areas (cells) rather than production or assembly lines. Production processes focused on smaller batches/bundles of custom products, can be either made-to-order (MTO) or made-to-stock (MTS). Work Cells usually organized to make a version of the product or performing most of the processing steps altogether. A portion of the process may be performed by automated equipment and selected labor operations executed by multifunctional working cells.

Process Manufacturing (Continuous)

Continuous manufacturing is referred to the production process where the materials are always in a state of motion or constant change. Allows things to be produced efficiently at scale, usually referred as mass production. Food processing or energy production are common examples.

Setting Up an Industrial Manufacturing Facility in Mexico: A Smart Business Move

Are you considering expanding your industrial manufacturing operations to Mexico? You're not alone! Many companies have already discovered the advantages of setting up an industrial manufacturing facility in Mexico. With its strategic location, skilled workforce, and favorable business environment, Mexico offers an attractive solution for companies looking to optimize their production processes and reduce costs.

Advantages of Manufacturing in Mexico

There are many reasons why Mexico vs China is simply the better solution: Mexico manufacturing represents the best of both worlds for manufacturing companies who seek to increase quality and production while reducing costs.

Viable Labor Pool

Low labor costs in Mexico provide many benefits than just a lower bottom line; see how your business can profit from utilizing the low-cost labor pool in Mexico.

Supply Chain Solutions

U.S.-made parts and products are used by Mexico manufacturers up to four times more than China; this is a tremendous benefit to suppliers in the United States.

Geopolitical Stability

The Mexican government is very friendly to foreign business and investment, as demonstrated by their 44 trade agreements with countries around the globe, including the recently-signed USMCA agreement.

Proximity to the US

Production is closer to the U.S. border; faster time to the consumer market than shipping across the Pacific Ocean, which can take weeks. Mexico manufacturing means lower transportation, trucks and trains as opposed to ships, and the abundance of warehousing make Mexico a cost-effective solution.

Are You Ready to Begin Manufacturing in Mexico? Contact Us for a Free Consultation

Contact us and let's start building something!

Use the details to the right to contact NovaLink.

Office

6665 Padre Island Highway

Suite B

Brownsville, Texas 78521

Hours

Mon-Fri: 8am - 5pm