Last Updated on May 21, 2024

The majority of business entrepreneurs who have a great product idea but lack the skills, knowledge, or equipment to get their project off the ground may need the assistance of a Mexico manufacturing partner that provides Full Package Manufacturing (FPM) or Full Service Manufacturing, as it is also commonly referred to.

Full-package manufacturing is well suited to Mexico, especially for companies looking to relocate their operations from China. Mexico's manufacturing industry has experienced significant growth over the past few decades, becoming one of the largest in the world. The country offers advantages for companies looking to outsource manufacturing. These include lower labor costs, favorable trade agreements with major economies such as the United States, and a skilled workforce.

Additionally, Mexico's geographic proximity to the United States makes it an attractive option for companies looking to reduce shipping times and costs. As a result, many companies from a variety of industries, including automotive, electronics, and medical devices, have established manufacturing operations in Mexico.

Different Types of Clothing Manufacturing

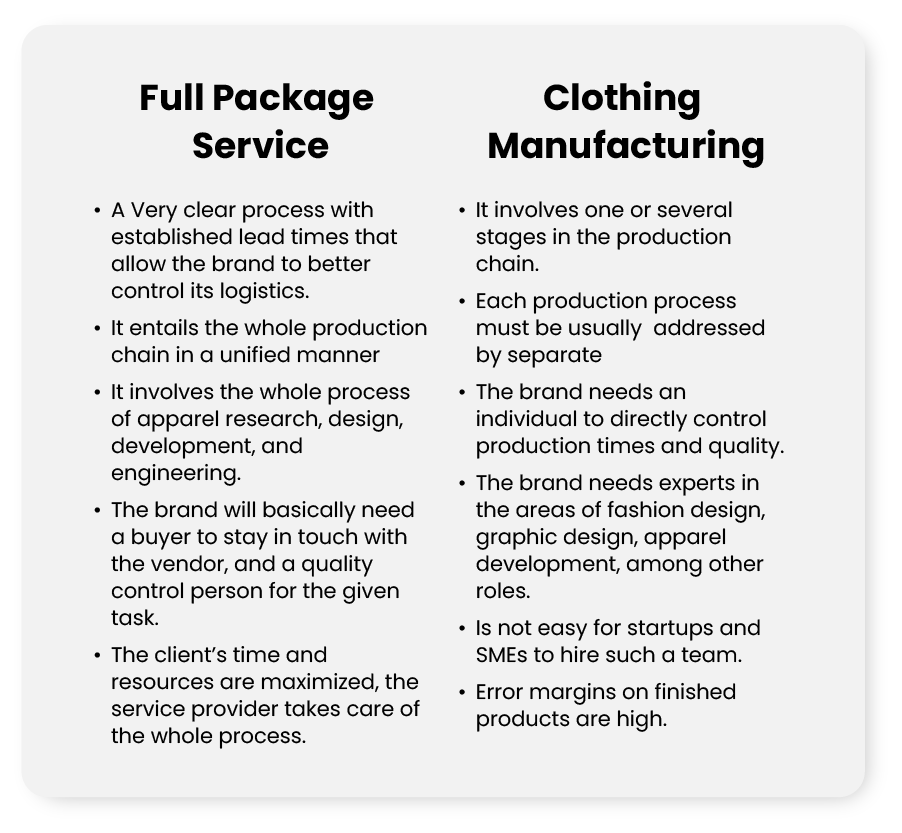

Generally, garment production can be divided into two categories. Choosing a CMT (Cut, Make, Trim) factory is the best choice if you want to maintain control over your processes. If your brand requires assistance with all aspects of production, an FPM (Full Package Manufacturing) might be right for you.

White paper: 5 Reasons Why Nearshore Manufacturing is a Perfect Fit for Mexico’s Textile and Apparel Industry

Mexico’s textile and apparel industries are becoming more diversified and expanding with newer investments in technology and infrastructure. If your company is seeking Mexico contract manufacturing for garment and textile manufacturing, there is no better fit than NovaLink. Here are 5 reasons why.

What Is CMT Manufacturing?

Cut, Make, Trim (CMT) manufacturing is a production process commonly used in the textile and apparel industry. It refers to a specific sequence of operations involved in creating a finished garment or product. Here's a breakdown of each stage:

- Cut: At this initial stage, fabric is cut into patterns and shapes according to the final product design specifications. This process typically involves using cutting dies or automated cutting machines to ensure accuracy and efficiency.

- Make: During the "make" stage, the cut fabric pieces are sewn together to create the basic structure of the garment or product. This may include assembling components like sleeves, bodices, or pant legs.

- Trim: At the final "trim" stage, any excess threads or yarns are removed, and the garment is finished with additional details like hemming, buttonholes, buttons, zippers, or other embellishments.

CMT manufacturing is often used for producing a wide range of textile products, including:

- Apparel (casual wear, formal wear, activewear)

- Home furnishings (curtains, upholstery)

- Industrial textiles (tarpaulins, canvas)

The CMT process offers several benefits, including:

- Efficient use of materials

- Reduced waste

- Improved quality control

- Increased productivity

- Cost-effectiveness

Many manufacturers, especially in the apparel industry, specialize in CMT production, offering services as contractors or partners to brands and designers. NovaLink, as a nearshore manufacturing partner, likely offers CMT manufacturing services to its clients. It leverages its expertise and resources in Mexico to support their production needs.

What is Full Package Manufacturing?

Full Package Manufacturing (FPM) is a manufacturing model where a manufacturing partner handles the entire production process, from design and prototyping to production and logistics. Essentially, the manufacturing partner takes on the responsibility of producing a finished product, which is then delivered to the company that outsourced the manufacturing.

FPM differs from other manufacturing models, such as Original Equipment Manufacturing (OEM) or Contract Manufacturing (CM), in that it provides a more comprehensive solution. In OEM or CM models, the manufacturing partner is typically responsible for a specific portion of the production process. This includes producing components or assembling products. In FPM, the manufacturing partner plays a larger role, handling the entire process from start to finish.

By utilizing an FPM model, companies can streamline their supply chain and reduce the number of vendors and partners they need to work with. This can lead to cost savings and improved efficiency, as the manufacturing partner takes on more responsibility for managing the production process. Additionally, FPM can help to reduce the risk of quality issues or delays, as the manufacturing partner is responsible for managing the entire process and ensuring that it runs smoothly.

By utilizing an FPM model, companies can streamline their supply chain and reduce the number of vendors and partners they need to work with. Share on XWhy is Mexico Perfect for Full Package Manufacturing?

When considering FPM, Mexico offers a unique combination of benefits that make it an attractive option. First and foremost, cost savings are a significant advantage. Labor costs in Mexico are significantly lower than in many other countries, making it an ideal location for companies looking to reduce expenses. Additionally, Mexico's strategic location allows for easy access to the US market, reducing shipping times and costs.

- Proximity to the United States: Mexico's close proximity to the United States makes it an attractive option for companies looking to outsource manufacturing. This reduces shipping times and costs, making it easier and more efficient to transport finished products to the US market.

- Favorable trade agreements: Mexico has several favorable trade agreements in place, such as the North American Free Trade Agreement (NAFTA) and the United States-Mexico-Canada Agreement (USMCA). These agreements provide significant benefits to companies, such as reduced tariffs and streamlined customs procedures, making it easier and more cost-effective to manufacture goods in Mexico and export them to other countries.

- Streamlined Production: One of the most significant benefits of FPM in Mexico is the streamlined production process. With a single manufacturer handling all aspects of production, communication is simplified, and the risk of errors is reduced. This streamlined approach also allows for faster production times, getting products to market quicker and giving companies a competitive edge.

- Expertise and Quality: Mexico has a large and skilled workforce, the Maquiladora, particularly in the areas of manufacturing and engineering. This expertise, combined with modern facilities and state-of-the-art technology, ensures that products meet the highest standards.

- Lower labor costs: Labor costs in Mexico are generally lower than in many other countries, including the United States and China. This can provide cost savings for companies looking to outsource manufacturing, as they can take advantage of the lower costs of labor in Mexico.

- Established manufacturing infrastructure: Mexico has a well-developed manufacturing infrastructure, including industrial parks, transportation networks, and supply chains. This makes it easier for companies to set up manufacturing operations in Mexico and take advantage of the existing infrastructure and resources.

Manufacturing capabilities in Mexico have evolved considerably since the pre-NAFTA days. Mexico now has a skilled workforce and boasts first-rate capabilities, with an abundance of expertise, especially in the automotive sector. Aerospace, medical equipment and appliances are also highly successful industries.

Mexico: an essential trade and manufacturing hub https://www.business.hsbc.com/en-gb/insights/growing-my-business/mexico-an-essential-trade-and-manufacturing-hub

What Should Companies Look for in a Full Package Manufacturing Partner?

The most important characteristic of a good full-service manufacturing partner is that he or she should possess the following: skilled labor, equipment, ample factory floor space, and most importantly, experience in producing quality textile products, ensuring any Mexican clothing manufacturing project is a success.

Ideally, the full package manufacturing partner should also provide the following skills and processes:

- Design Consultation / Engineering

- Pattern Making

- Prototyping & Sampling

- Pattern Making

- Grading & Nesting

- Fabric / Component Sourcing

- Technical Design & Quality Control

- Process Engineering

- Time studies

- Line Layout

- Cutting

- Sewing

Overall, FPM and working with a manufacturing partner based in Mexico can provide significant benefits to companies looking to outsource manufacturing, including cost savings, improved efficiency, and access to a skilled workforce and established infrastructure.

FAQs about Full Package Manufacturing

Q1: What is full package manufacturing?

A1: Full package manufacturing refers to a comprehensive manufacturing service where a single provider handles the entire production process, from sourcing raw materials to final product delivery. It includes various stages such as design, prototyping, sourcing, production, quality control, packaging, and logistics. The full package manufacturer takes responsibility for managing the entire manufacturing process on behalf of the client.

Q2: What are the benefits of opting for full package manufacturing?

A2: Opting for full package manufacturing offers several benefits. It provides convenience and saves time as the client doesn't have to coordinate with multiple suppliers or manage different aspects of manufacturing. It ensures better quality control as the full package manufacturer oversees the entire process. Additionally, it can lead to cost savings by streamlining operations, optimizing production efficiency, and leveraging the full package manufacturer's expertise and supplier networks.

Q3: Is full package manufacturing suitable for all types of products?

A3: Full package manufacturing is suitable for a wide range of products across various industries. It can be particularly beneficial for complex or custom products that require coordination between different manufacturing stages. Industries such as apparel, consumer goods, electronics, and furniture often utilize full package manufacturing services to streamline their production processes.

Q4: How does the client maintain control and visibility over the manufacturing process?

A4: Despite outsourcing the manufacturing process to a full package manufacturer, the client can maintain control and visibility. Communication and collaboration play a vital role in maintaining transparency. The client can set clear expectations, provide detailed product specifications, and establish regular reporting and updates with the full package manufacturer. This ensures the client remains informed and involved throughout the manufacturing process.

Q5: What factors should be considered when choosing a full package manufacturer?

A5: When choosing a full package manufacturer, factors to consider include their experience and expertise in the specific industry, their manufacturing capabilities and capacity, quality control measures, their supplier network, track record, and their ability to meet timelines and cost targets. It is essential to evaluate their communication and project management processes to ensure a smooth and successful collaboration.

About NovaLink

As a manufacturer in Mexico, NovaLink employs a unique approach that transcends the traditional model of shelter production. More than just the location of your manufacturing, we would like to become a partner in your manufacturing in Mexico. You will be able to relocate or initiate manufacturing for your company in Mexico in a low-cost labor environment with very little delay or up-front costs. Find out how we can help you by handling the manufacturing process.

There are NovaLink facilities in the border cities of Brownsville, Texas, Matamoros, Mexico, and Saltillo, Mexico.